Published in Windlesora 23 (2007)

© WLHG

John Corby came to Windsor from his native Scotland in 1929 as a business consultant to the Berks and Bucks Motor Company at 6 Frances Road Windsor. He advised them to go into liquidation, then bought the company himself and turned it around and subsequently sold it. He also leased the property at 28 Francis Road, Windsor from the Crown for 21 years, where for a time my own father, Reg Try, parked some of the Charabancs of his new Windsorian coaches for 7/6 (35.5 pence) a week.

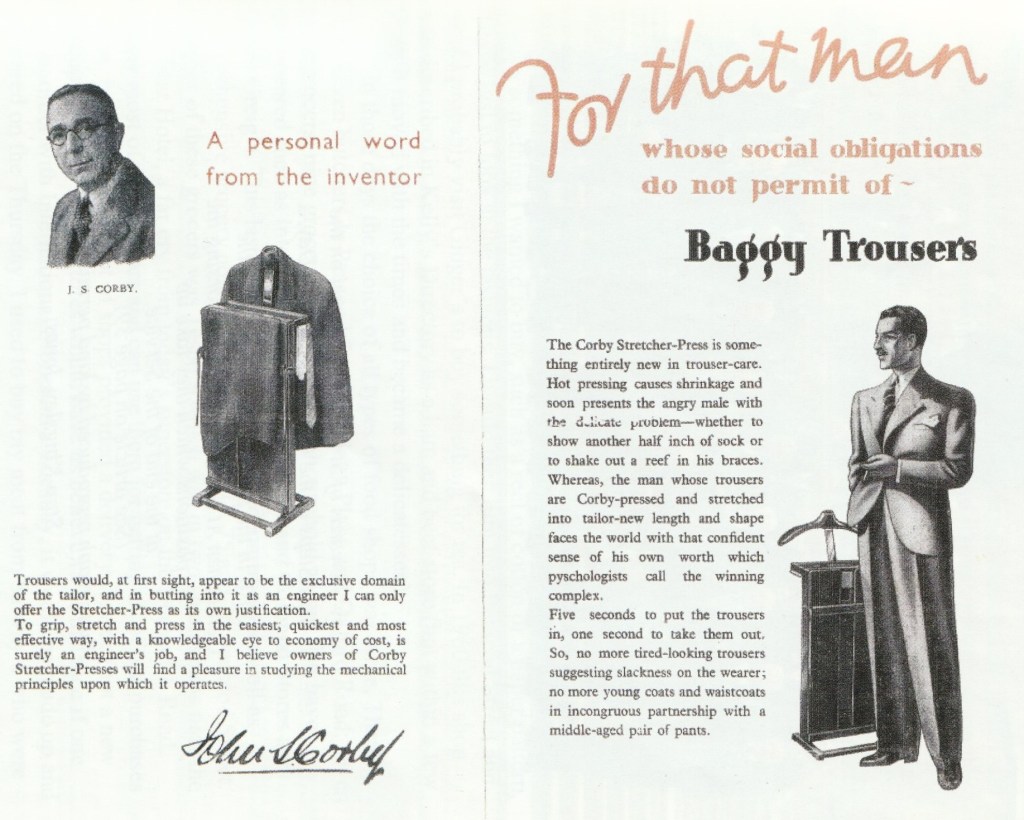

In 1931 John Corby had made for himself a new type of trouser press, which he fitted inside his wardrobe door. When his good friend Austin Reed saw it, he was impressed, and suggested that if it were free standing his shops would sell it. To John’s amazement he put in a first order for 72 presses and Corby’s Ltd was immediately inaugurated and registered. Initially the metal parts were stamped out at 28 Francis Road, and the woodwork came from High Wycombe. By 1935 sales exceeded 5,000 trouser presses a year and the manufacturing, including the woodwork, was done at 28 Frances Road.

John’s son Peter joined the factory in 1939 at a salary of £1.1s (£1.05) a week, shovelling up sawdust and sweeping the floor, but with the outbreak of war the factory had to close for lack of materials. Peter Corby joined the RAF, the machinery was stacked into a corner, and the property was leased to Timothy Whites, whose storage building in Portsmouth had been bombed out.

After the war, John reopened the factory, but he soon hit trouble. His manager sacked the bookkeeper, John reprimanded the manager, who promptly resigned, and nobody got paid. Then John had a serious heart attack. Peter was asked to come back, and in 1949 he returned at a salary of £1,000 a year. His father died in 1956 after a series of heart attacks.

During the 1950s crease resistant materials rendered the trouser press ineffective and sales slumped. So the factory made cots for Mothercare, garden furniture for Sutton Seeds and many other products. Then Peter had the idea of a heated trouser press, and in 1960 with the help of a Concorde scientist and the science laboratory at Eton College, a flexible heating pad was developed which would press the most obstinate materials without damaging the most delicate.

The new trouser press was greeted with scepticism as a thing of the past. No one believed it would sell, let alone for £25. Harrods took a chance and ordered nine, but Austin Reed’s son, Barry Reed would only take three per shop on a sale or return basis. Within twelve months, however, Austin Reed sold more than 600, and Harrods sold over 1,500. By 1973 production was running at the rate of 80,000 presses a year, this decided Peter Corby that it was a good time to sell out.

Geoff Try

By kind permission of Peter Corby